Perfect CAD/CAM Integration Software

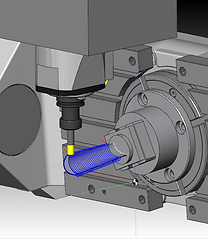

SolidCAM multi-axis turn-mill machine and the perfect solution for the machining path of high-end centering turn-mill machine SolidWroks certified gold integration partner allows you to seamlessly transition from CAD to CAM and shorten the learning curve. Introducing AI to assist CNC cutting, effectively improving tool life and processing efficiency

生命是所有重要決定的總和,這些決定可能在沒有完整事實的情況下做出,但卻基於直覺、勇氣和大膽而得!

With over 37 years of experience in the development and support of SolidCAM, we have created the most powerful CAM solution that takes your CNC machines to maximum productivity. Today, we are the leading independent CAM company with of more than 250 dedicated developers, application engineers and sales staff as well as a global reseller network all over the world.

Seamless CAM-Integrations

Founded in 1984 by Dr. Emil Somekh, SolidCAM's strategy of integrating with the most popular CAD systems has created tremendous growth and established SolidCAM as the ultimate solution for integrated CAM systems. SolidCAM as a Certified Gold-Product for SOLIDWORKS and InventorCAM, an Autodesk Certified Product, provides seamless, single-window integration and full associativity to the SOLIDWORKS and Inventor design models.

iMachining – Revolution in CAM

Around the globe, SolidCAM is extremely popular for its powerful iMachining module. iMachining – a revolutionary milling technology, provides unmatched time savings (often more than 70% and more in machining time), guided machine settings (using patented iMachining Wizard), increased efficiency, and incredible CNC machine performance in all CNC milling operations.

The Future of CAM

SolidCAM's growth is driven by its unmatched dedication to successful customers and providing the most advanced machining technology in the industry. In addition to iMachining and the incredible CAD integration, SolidCAM also revolutionized how advanced Mill-Turn and Swiss-Type CNC machines are programmed, providing the most incredibly powerful and easy-to-use tools to program even the most complex machines. Recently, SolidCAM radically advanced tool table functionality that directly benefits Advanced Mill-Turn and Swiss-Type applications in a truly realistic graphic simulation environment. SolidCAM has also created a new suite of shop-floor editor and simulation applications directly designed for machine operators.

High-level tool-type turning and milling compound

Advanced Multi-turret/Multi-spindle Lathe-Milling Compound Machine's Comprehensive Solution, a mature multi-channel lathe-milling compound system that maximizes the combination of milling and turning operations to manufacture workpieces with the highest productivity.